Система челночных стеллажей для компании AJ Solution, Парагвай

Nov 12, 2025Обзор проекта

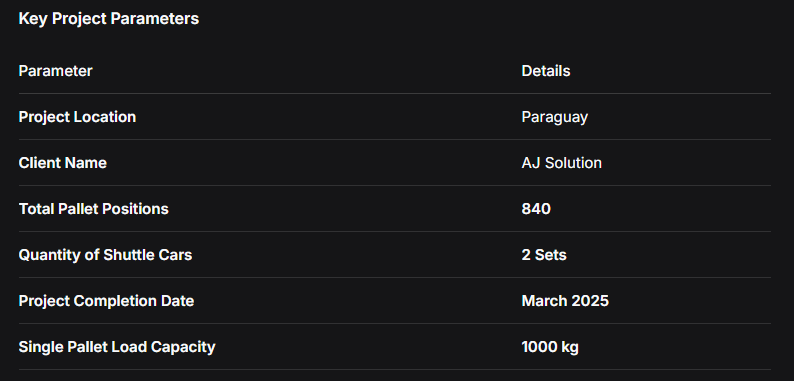

Мы с гордостью представляем проект высокопроизводительной полуавтоматической стеллажной системы для нового современного склада компании AJ Solution в Парагвае. Этот проект призван создать высокоэффективное и интеллектуальное решение для хранения с высокой плотностью размещения товаров, которое удовлетворит растущие логистические потребности клиента и значительно повысит его производительность. Полная ввод в эксплуатацию и передача объекта запланированы на март 2025 года.

Предыстория и проблемы

В условиях стремительного расширения бизнеса компания AJ Solution столкнулась со следующими ключевыми проблемами:

Низкая эффективность использования складских площадей: традиционные стеллажные системы оказались недостаточными для хранения больших объемов товаров, что привело к низкой эффективности использования земельных участков.

Необходимость повышения производительности: ручная или традиционная работа с использованием вилочных погрузчиков создавала узкие места, затрудняя выполнение заказов в пиковый сезон.

Требования к точности учета запасов: Необходимы точное управление запасами и быстрая инвентаризация.

Затраты на рабочую силу и безопасность: Необходимо сократить взаимодействие пешеходов и погрузчиков для снижения затрат на рабочую силу и минимизации рисков для безопасности.

Решение: Высокоэффективная система подвесных платформ для челночных перевозок.

Наше ключевое решение — внедрение передовой полуавтоматической стеллажной системы. Эта система идеально сочетает в себе плотность хранения, эффективность эксплуатации и инвестиционные затраты.

Основные компоненты системы:

Стеллажная конструкция: Высокопрочная стальная стеллажная система, разработанная для обеспечения устойчивости и долговечности, обеспечивающая надежную основу.

Тележки-шаттлы (2 комплекта): Проект будет оснащён двумя (2) комплектами высокопроизводительных тележек-шаттлов с радиоуправлением. Эти тележки перемещаются по рельсам внутри стеллажных линий, автоматически управляя хранением, поиском и позиционированием поддонов — они являются сердцем автоматизации.

Система управления: программное обеспечение интегрированной системы управления складом для интеллектуальной диспетчеризации задач по перевозкам, оптимизации маршрутов забора и сдачи товара, а также обеспечения прозрачности запасов в режиме реального времени.

Системный рабочий процесс:

Оператору погрузчика достаточно разместить поддон у обозначенного входа в стеллажную зону. С помощью пульта дистанционного управления или системной команды запускается челнок. Челнок автоматически принимает поддон и транспортирует его в оптимальное доступное место в глубине зоны для хранения. Для извлечения челнок доставляет запрошенный поддон к входу в зону, где его забирает погрузчик. Этот принцип «товар к человеку» значительно сокращает время перемещения погрузчика и время ожидания в проходах.

Ключевые параметры проекта

Максимальное использование пространства: Высокая плотность размещения стеллажей увеличивает вместимость хранения на 80% и более по сравнению с традиционными стеллажами селективного типа, обеспечивая значительную экономию на арендной плате.

Значительно повышенная эффективность: Два челночных вагона могут работать параллельно, обеспечивая быструю и точную обработку грузов. Это сокращает время цикла работы погрузчика и пройденное расстояние, что приводит к существенному увеличению производительности.

Снижение эксплуатационных расходов: Минимизирует количество необходимых проходов и зависимость от высококвалифицированных водителей погрузчиков, что снижает долгосрочные затраты на рабочую силу и энергию.

Превосходная безопасность и устойчивость: Система рассчитана на нагрузку до 1000 кг, что обеспечивает её структурную целостность. Сокращение взаимодействия человека и машины минимизирует риск несчастных случаев и повреждения продукции.

Точное и прозрачное управление запасами: система точно отслеживает местоположение и статус каждого поддона, обеспечивая прозрачность запасов в режиме реального времени и точный учет для принятия более обоснованных решений.

Заключение

Проект по модернизации стеллажного оборудования для компании AJ Solution в Парагвае — это не просто обновление складских помещений; это стратегический шаг к интеллектуальному, современному управлению логистикой. В случае успешной реализации этот проект создаст высокоэффективный, надежный и перспективный распределительный центр, который окажет мощную поддержку стратегическому росту клиента на парагвайском и более широком рынках Южной Америки.

Мы рассчитываем на тесное сотрудничество с компанией AJ Solution для обеспечения успешного завершения проекта в марте 2025 года, что установит новый стандарт для промышленного складского хозяйства в регионе.

Add: NO.409 West Jianshe Road, Economic Development Zone, Jinhu County, Jiangsu Province, China

Авторские права

2026@ Jiangsu Kingmore Storage Equipment Manufacturing Co., Ltd Все права защищены.

Карта сайта

| Блог

| Xml

| политика конфиденциальности

ПОДДЕРЖИВАЕТСЯ СЕТЬЮ

ПОДДЕРЖИВАЕТСЯ СЕТЬЮ